Efficient Equipment BoM

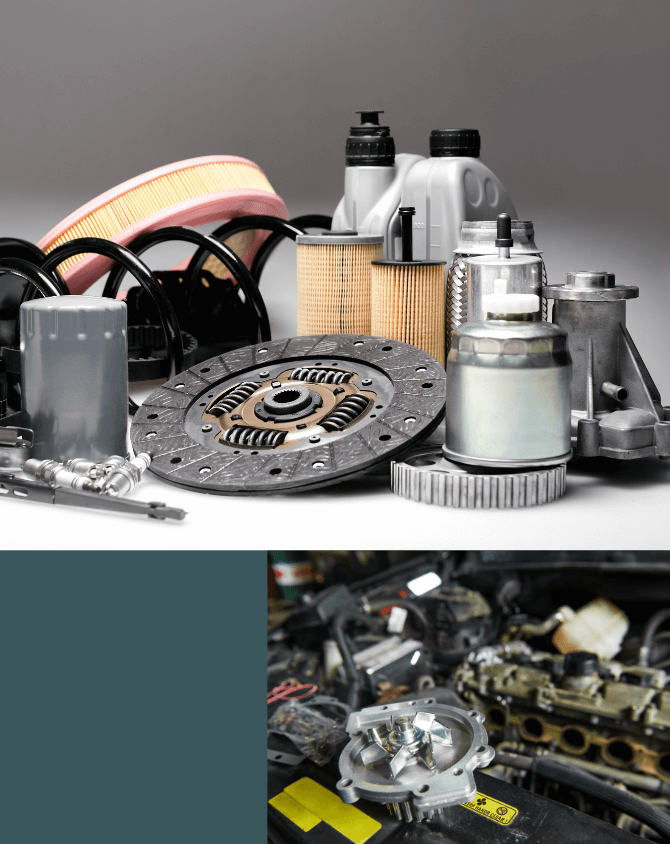

Our skilled resources are instrumental in the creation and upkeep of precise Equipment Bill of Materials (BOM), a task that lies at the core of efficient maintenance and repair operations. By meticulously cataloging every essential component and spare part required for equipment upkeep, our experts ensure a comprehensive overview of the necessary resources.

This precision translates into tangible advantages for our clients. Firstly, having a detailed and accurate BOM streamlines the procurement process significantly. It means that necessary parts and components can be sourced swiftly and efficiently, reducing the time spent on hunting down materials. This agility in procurement directly translates into minimized downtime during maintenance, enhancing the overall operational continuity of our clients' facilities.

Moreover, maintaining a comprehensive BOM elevates overall operational readiness. With every critical element documented with precision, our clients have a clear roadmap for maintenance activities. This clarity not only facilitates smooth repairs and replacements but also aids in strategic planning. Predictive maintenance becomes more accurate, enabling proactive measures to prevent potential issues.

In essence, the meticulous documentation of BOM ensures not just the availability of spare parts but also strengthens the resilience of our clients' operations. By reducing downtime, improving strategic decision-making, and enhancing overall efficiency, our clients can rely on us to maintain their equipment effectively, ensuring uninterrupted operations and optimized performance in their respective industries.

Effective detailed and accurate list of components and parts needed to construct or maintain a piece of equipment. Here are five key features of an effective and precise Equipment BOM:

Comprehensive Component Listing

Clear Hierarchy and Structure

Precise Part Descriptions and Specifications

Revision Control

Quantity Accuracy and Sourcing Information

Do you have any question?

Let's connect

Email: info@innovarabia.net